So, update on the last few weeks. A lot happened, so I'm just going to try to go in order.

Basically, we took a crash course in mechanics trying to figure out if our idea of a cantilevered beam hanging over the side of the dock was even vaguely feasible and/or safe. Here are some beautiful pictures of that exceptionally long and painful experience:

|

| The Original Plan |

|

| The pretty picture |

|

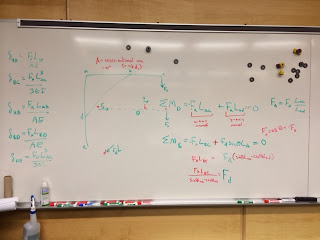

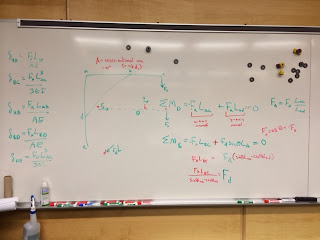

| The "hey professor, we don't know what we're doing" |

|

Trying desperately to remember physics. And combine it with our math knowledge.

Let's be honest, we kinda just listened to Prof. Banzaert at this point. |

|

| I thought I'd include a picture of the whole board because it makes us look smart. |

|

Then we tried to remember geometry...and trig...it took us an embarrassingly long time to do this...

But...but...we can do multivariable calculus....usually... |

We then changed the materials, type of beam (between tubes, pipes, and rods), and the measurements of the beams about a zillion times trying to find one that had a deflection percentage of less than 0.05% in all of the pieces of the beam. This took us approximately forever, and we couldn't find one that fit the criteria, so we concluded that the cantilevered beam, even with a support strut, was not a good option. Also, the support strut would have to be so across half of the beam, making it very difficult to shimmy along.

|

| The diagram for this prototype, along with the anthropometric measurements we used to determine its size |

|

| The diagram for this prototype, drawn to scale |

So we looked at some other options:

And we took a trip to a playground (for science!):

|

| I was too tall to use the bar... |

|

| Pretend that that scarf is a metal pole. |

And determined that having the vertical bar right in the middle of the horizontal bar would not really be a problem in terms of how easy or difficult it would be to shimmy across the bar. After a little bit of tinkering with our equations (read 2 hours), we determined that, with the right material, this idea would be feasible if we use 1.75" (diameter) "Easy-to-Weld Wear-Resistant 8620 Alloy Steel" rods and weld them together (yay!). The diameter was determined by a combination hand anthropometry statistics and Amy and me running around the library hanging off of random bars (and measuring them because we are just that scientific).

|

| The funny part was that we didn't get any weird looks doing this... I don't know what that says about our college... |

|

| This makes it science! |

Unfortunately, the full size prototype will be very expensive, so we started building a prototype (complete with dock and wheelchair) with a 1/343 scale:

|

| The diagram for our newest prototype, drawn to scale |

|

| Calculating the scale of our prototype |

|

The first prototype

(made with random materials and very inexpert techniques, i.e. hot glue and smashing wire to bend it over)

The rod that we ordered to make our next prototype.

It is the same rod that we want to use for our full-size prototype, but at a 1/343 scale. |

|

| The diagram for the dock |

|

| The halfway-finished dock (to scale - we estimated the size of their dock) |

|

| Diagrams and calculations for the scale model of the wheelchair |

|

| The wheelchair model before printing |

|

| An Amy in her natural habitat. |

We will be showing our finished scale prototype to Community Rowing to get feedback before we make the final purchase because we don't want to damage any of our expensive materials making a full size prototype before we are sure that the product will work and be useful. Also, in order to safely and securely attach the vertical pole to the dock, we will need to use a crane base, cost hundreds of dollars at least, so we are going to give our plans to CRI and see if they want to implement it.

.JPG)